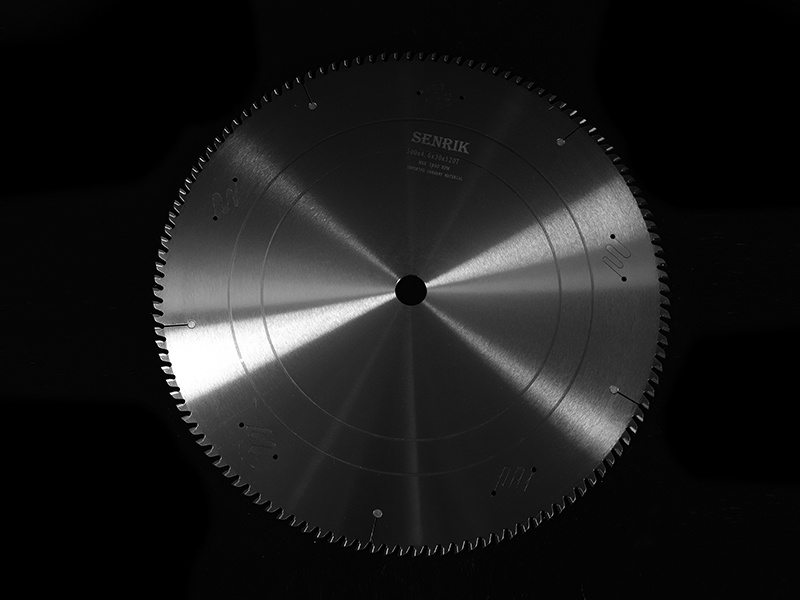

10"(255)*3.0*25.4*120T

Classification:

Small size

In modern industry and daily life, cutting operations are everywhere, from metal processing, wood manufacturing to stone mining, every link cannot do without efficient cutting tools.

Keyword:

10"(255)*3.0*25.4*120T

Contact Us

External trade: 86-13703066097

E-mail:13703066097@139.com

Enterprise advantage

In modern industry and daily life, cutting operations are everywhere, from metal processing, wood manufacturing to stone mining, every link cannot do without efficient cutting tools. As a core equipment in the cutting field, saw blades have become the preferred choice for many industries due to their excellent performance and wide applicability. It continuously promotes the innovation and development of cutting technology with multiple advantages such as efficiency, precision, and durability, and can be regarded as the all-around king in the cutting field.

1、 Efficient cutting, improving work speed

One of the most significant advantages of saw blades is their efficient cutting ability. Compared with traditional cutting tools, saw blades generate strong cutting forces through high-speed rotation, which can quickly cut materials. Taking metal processing as an example, high-performance metal saw blades can reach thousands of revolutions per minute, and can complete cutting tasks in a short period of time when facing hard metals such as steel and aluminum. In the wood processing industry, circular saw blades play a huge role. Their sharp serrations can easily cut into wood, greatly improving the efficiency of wood processing and meeting the rapid processing needs of industries such as furniture manufacturing and construction decoration for a large amount of wood. In some large wood processing plants, the application of multi blade saws has raised the efficiency of wood cutting to a new height. Multiple boards can be cut simultaneously with one feed, greatly shortening the production cycle.

2、 Precise cutting ensures the quality of the finished product

In addition to efficiency, the precision of the saw blade is also commendable. With the continuous advancement of manufacturing technology, the cutting accuracy of saw blades has been greatly improved. The precision grinding teeth and high-precision manufacturing process enable the saw blade to maintain a stable cutting trajectory during the cutting process, controlling cutting errors within a very small range. In industries such as electronic manufacturing and precision instrument processing that require high precision, the precise cutting ability of saw blades is particularly important. For example, cutting semiconductor chips requires the use of ultra-thin diamond saw blades, which can cut chips into the required size with micrometer level accuracy, ensuring the performance and quality of the chips. In the jewelry processing industry, saw blades can accurately cut various gemstones, preserving their weight and value to the maximum extent possible while ensuring a smooth and even cutting surface.

3、 Durable and wear-resistant, reducing usage costs

The durability of the saw blade is also an important advantage. High quality saw blades are usually made of materials with high strength and wear resistance, such as hard alloys, high-speed steel, diamond, etc. These materials endow the saw blade with excellent wear resistance, enabling it to remain sharp during prolonged cutting operations and reducing the frequency of replacement. Hard alloy saw blades can work continuously for a long time without significant wear even when facing high-intensity workloads when cutting metals. Diamond saw blades have a much longer service life than ordinary saw blades due to their ultra-high hardness and wear resistance when cutting hard materials such as stone and concrete. Although the initial purchase cost of high-quality saw blades is relatively high, their durability can significantly reduce overall usage costs and minimize downtime and material waste caused by frequent blade replacement over long-term use.

4、 Widely applicable, meeting diverse needs

The application range of saw blades is extremely wide, covering almost all industries that require cutting. According to different materials and cutting requirements, there are various types of saw blades to choose from, such as woodworking saw blades, metal saw blades, stone saw blades, glass saw blades, etc. Each type of saw blade is optimized for specific materials to ensure the best cutting effect. In construction, concrete saw blades can quickly cut reinforced concrete structures, providing convenience for building renovation, road construction, and other projects; In the plastic processing industry, specialized plastic saw blades can achieve precise cutting of various plastic products. In addition, with the development of technology, multifunctional saw blades have gradually emerged, which can adapt to cutting various materials and further expand the application scenarios of saw blades.

5、 Technological innovation leads the development of the industry

The saw blade industry has always maintained strong innovation vitality, constantly introducing new technologies and processes to promote the continuous improvement of saw blade performance. For example, the application of coating technology has brought better wear and corrosion resistance to saw blades; The development of new materials has led to new breakthroughs in hardness, toughness, and other aspects of saw blades; The emergence of intelligent saw blades has pushed saw blade technology to a new height. Intelligent saw blades can monitor the working status of the blade in real time, such as temperature, wear degree, etc., through built-in sensors, and feedback the data to the control system to automatically adjust cutting parameters and improve cutting safety and efficiency. These technological innovations not only enhance the performance of the saw blade itself, but also inject new impetus into the development of the entire cutting industry.

Saw blades have become an indispensable tool in the cutting field due to their many advantages such as high efficiency, precision, durability, and wide application. With the continuous advancement of technology, the performance of saw blades will be further improved, and their application scenarios will continue to expand. In the future industrial production and daily life, saw blades will continue to play an important role, providing strong support for the development of various industries.

The above article demonstrates the advantages of saw blades from multiple perspectives. If you feel that certain content needs to be supplemented or adjusted, such as focusing on the advantages of specific types of saw blades, please feel free to let me know at any time.

Other Products

Product Consulting